Concept & Design

Concept & Design

Our expertise begins at the conceptual stage where we assist clients in refining their product ideas, ensuring manufacturability, and optimizing performance. We use cutting-edge software for 3D modeling, prototyping, and design validation, allowing for rapid iteration and development.

“It has been a true pleasure teaming up with Mission Plastics. Mission continues to anticipate our needs and deliver results.”

— Bill Campbell, Director of Plant Operations, Safety Syringe, a Beckton Dickinson Company

Engineering & Design Capabilities

- DFM (Design for Manufacturability): Ensuring designs are optimized for efficient production while minimizing costs.

- Material Selection: Expertise in choosing the right thermoplastics for durability, strength, and environmental factors.

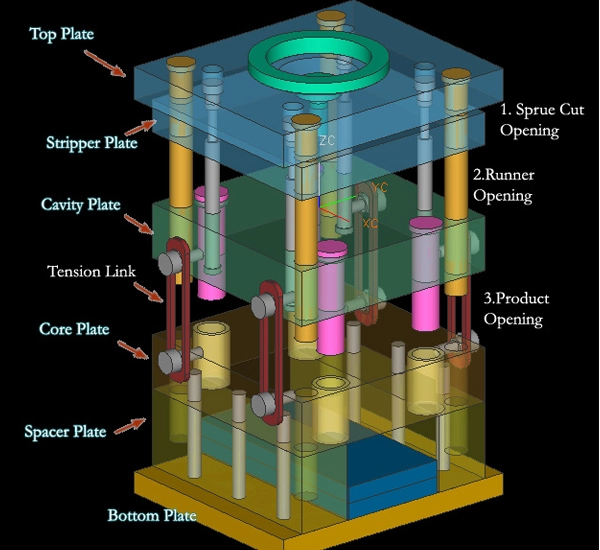

- Tooling & Mold Design: Precision mold development using advanced CAD/CAM technology.

- Rapid Prototyping: 3D printing and test molding for early-stage evaluations.

- Finite Element Analysis (FEA): Simulating stress, load, and thermal dynamics for optimal part performance.