Engineering Experts with

Manufacturing Solutions

Capabilities

"Mission Plastics: Your trusted partner for high-quality custom plastic manufacturing solutions."

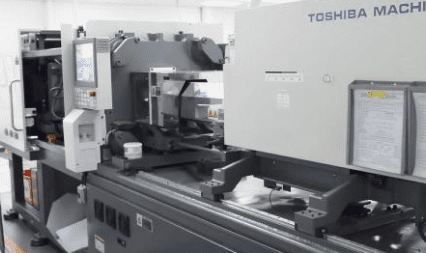

Manufacturing

Reliable. Efficient. Innovative. Precision injection molding for medical, automotive, and consumer industries.

Quality & Compliance

Trusted. Precise. Compliant. Upholding quality and regulatory standards in every injection-molded product we create.

Project Onboarding & Speed to Market

Strategic. Streamlined. Accelerated — Expert-led onboarding and execution that eliminate delays and fast-track your product to market.

Concept & Process Design

Innovative. Creative. Functional. Transforming ideas into precise, manufacturable injection-molded designs.

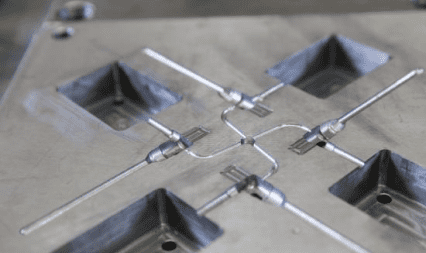

Tooling & Prototyping

Precise. Adaptive. Reliable. Expert tooling and prototyping for flawless injection-molded production.

Fulfillment & Logistics

Efficient. Accurate. Timely. Seamless fulfillment and logistics to keep your supply chain moving.

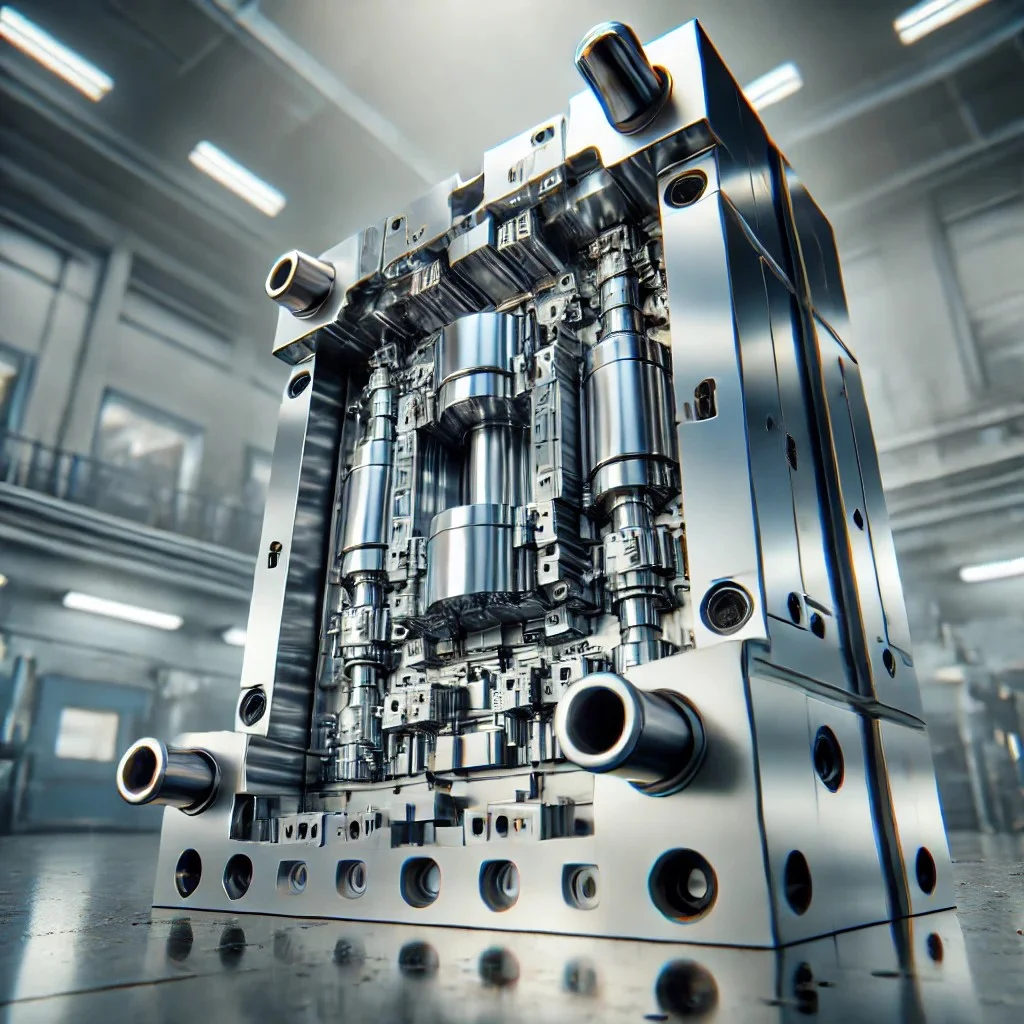

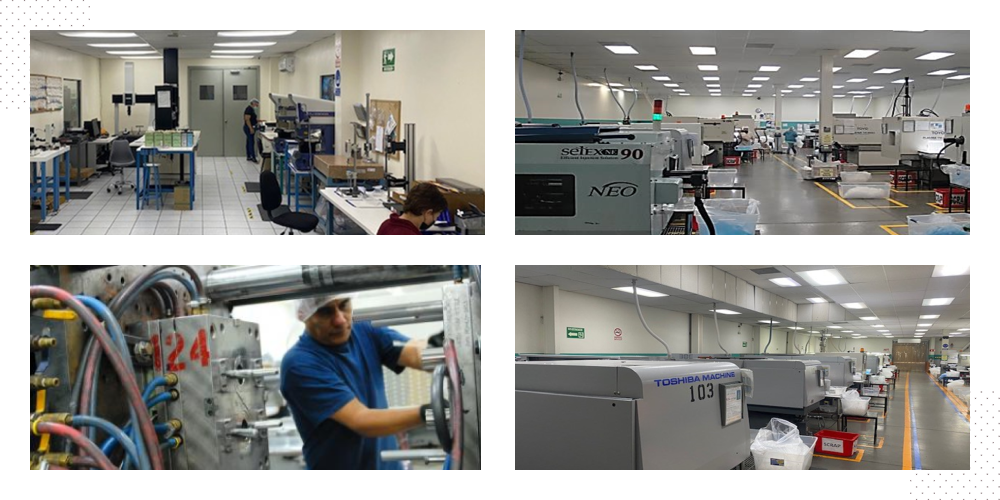

Facilities & Equipment

Modern. Capable. Cutting-Edge. State-of-the-art facilities and equipment for superior injection molding.

Industries Served

OEM Solutions for Industry

With over three decades of manufacturing experience, Mission Plastics Inc. operates 24/7 to provide high- or low-volume customers with the facilities, technical experts, and resources to manage a project from mold making through final fulfillment, producing superior molds and custom plastic products at the most exacting specifications and inspection requirements. Learn More

Scientific molding services include Injection Molding, Insert Molding and Micro-molding, produced with organizational excellence and ISO Quality standards. (ISO 13485)

Industries Served

Medical

A strategic focus for Mission Plastics is our ability to provide comprehensive tooling, mold validation, injection molding and production for medical and life science products.

Automotive

Mission Plastics Inc. applies its operational excellence, complete design assistance and comprehensive tooling capabilities to create competitively priced automotive parts.

Commercial

From consumer product components to electrical enclosures to fittings for irrigation equipment, and more, Mission Plastics Inc. prides itself on the success of delivering .

Certified ISO-13485 Quality

All products designed and manufactured by Mission are delivered with the highest level of quality control.

Exceptional quality and customer experience is the measure of our work—it is the cornerstone of our reputation as an industry leader.

~ Robert Guy, President of Mission Plastics.

MANUFACTURING PLANT CAPABILITIES

Rancho Cucamonga, Corp. Office

Rancho Cucamonga, Corp. Office

- Onsite Metrology Lab & Tool room

- Integrated Program Management

- Concurrent Engineering / DFMA

- In-house Automation / Mold Design & Tooling

- Lean Design & Manufacturing

MANUFACTURING PLANT CAPABILITIES

Mexicali, Mexico

Mexicali, Mexico

- ISO 13485 Certified

- Press Tonnage available 7 - 720 Tons

- 7 - 310 Tones - Under ISO Class 8 Clean Room

- Onsite Metrology Lab & Tool room

- Integrated Program Management

- Concurrent Engineering / DFMA

- Mold Design & Tooling

- Lean Design & Manufacturing

About Us

Founded in Ontario, CA, in 1982, Mission Plastics Inc. (MPI) is a full-spectrum custom injection-molding manufacturer for world-class customers in the Medical, Automotive and Commercial industry sectors

By providing a systematic and full-service plastic molding experience, Mission Plastics will meet and satisfy our customers’ requirements with the highest quality – and added value – by continually improving the effectiveness of our Quality Management System.

100%

Dedicated to Quality

41+

Years of experience

Testimonial

What they're saying about

Mission Plastics.